Special and Low Friction Systems

Unique Applications and Custom Engineered Products to Solve the Toughest Challenges

REDUCE MAINTENANCE AND EXTEND LIFE ON A WIDE RANGE OF APPLICATIONS

Kamatics is capable of creating a wide range of engineered products with self-lubricating KAron™ technology to solve the toughest application challenges.

Our Karon™ Engineered Products Are Used in Numerous Applications Across Several Industries, Including:

Commercial Fixed Wing Aircraft

Aircraft Bearings for Commercial Aviation Systems

Aviation bearings engineered for reliability in commercial fixed-wing aircraft landing gear, flight control systems, doors, vertical and horizontal stabilizers. Kamatics aerospace bearings provide grease-free, maintenance-free operation in flight control assemblies and stabilization systems for major aircraft manufacturers.

Commercial and Military Helicopters

Helicopter Bearings for Rotor and Flight Control Systems

Kamatics self-lubricating bearings deliver maintenance-free performance in mission-critical helicopter applications including flight control systems, landing gear systems, damper bearings, swash plate bearings, pitch control systems, and rotor control systems. Our KARON™ spherical bearings and rod end bearings provide reliable, grease-free operation in military rotorcraft and commercial aviation platforms.

Engines

High-Temperature Aerospace Bearings for Engine Components

Specialized self-lubricating bearings for extreme engine environments including turbines, cowlings and doors, and thrust reversers and nacelles. KARON™ high-temperature liners operate continuously up to +700°F, providing reliable performance in high-temp engine systems without grease breakdown.

Space Vehicles and Satellites

Aerospace Bearings for Space and Satellite Applications

Mission-critical bearings for vacuum and extreme temperature environments including flight control systems, power systems, solar array deployment systems, and fuel tank attachment points. Kamatics custom engineered bearings feature low-outgassing KARON™ formulations designed for space applications, with proven performance in thermal cycling and extreme conditions.

Marine

Corrosion-Resistant Marine Bearings for Naval Systems

Self-lubricating bearings engineered for harsh saltwater environments including navigational lock systems, power generation systems, and steering and diving mechanisms. KARON™ liner technology features no moisture path, preventing corrosion that causes premature failure in naval vessels, submarines, and offshore platforms.

Hydropower

Industrial Bearings for Hydropower Systems

Maintenance-free bearings for large-scale hydroelectric systems including gate systems and Kaplan hub transition mechanisms. Kamatics spherical bearings and bushing bearings provide reliable performance in turbine blade angle adjustment and water flow control, eliminating costly downtime and lubrication requirements.

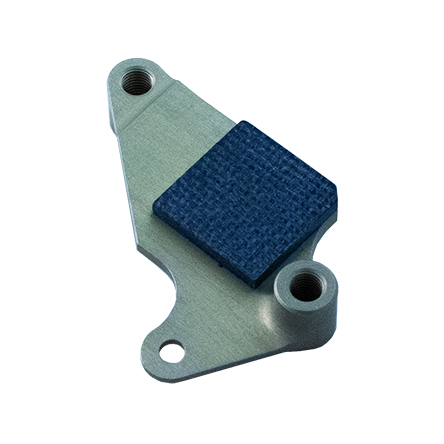

KAMATICS BEARINGS ARE MADE WITH KARON™ SELF-LUBRICATING LINERS, AVAILABLE IN A RANGE OF VARIETIES

Our liners differ significantly from other self-lubricating materials in that there are no continuous interconnecting fibers or weave that can provide a moisture path to the bonding substrate. A moisture path can promote corrosion under the liner or significant liner swelling when used in a moisture-laden environment.

OTHER EXCEPTIONAL KAMATICS PRODUCTS

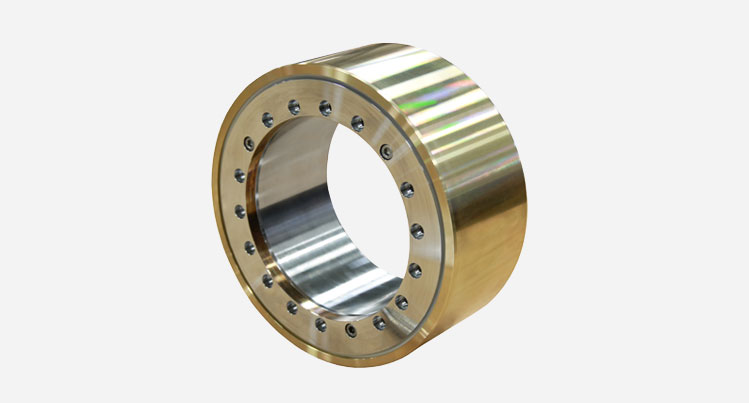

Spherical & Link Bearings

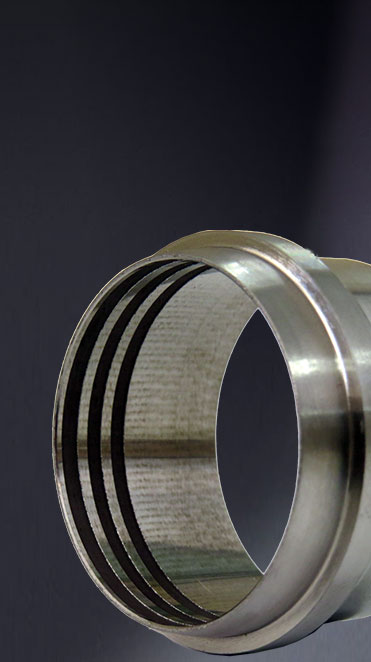

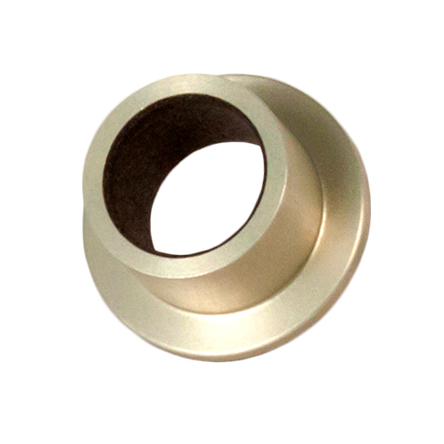

Bushings and Journal Bearings

Track Rollers and Needle Rollers

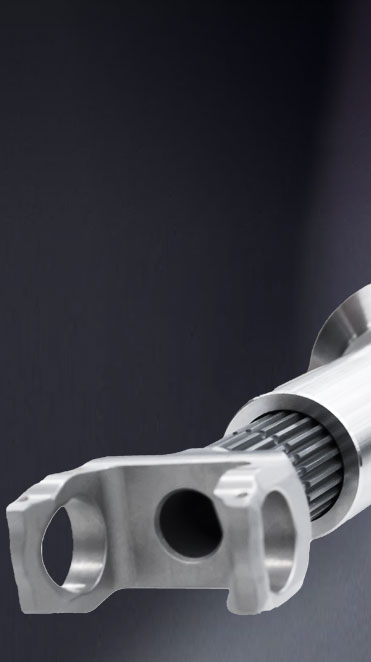

Flexible Drive Systems